건너뛰기 링크

주메뉴 및 상단메뉴

A leading company in the global refrigeration industry

Our priority is in differentiating our products and customer satisfaction.

본문 및 주요 콘텐츠

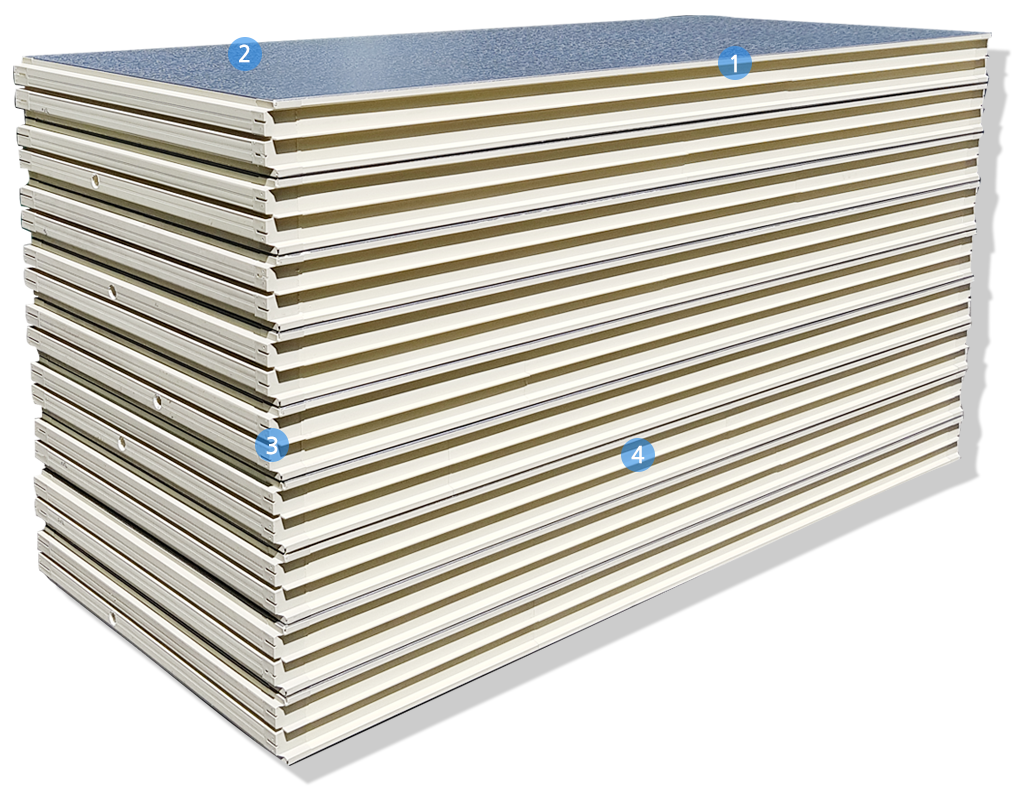

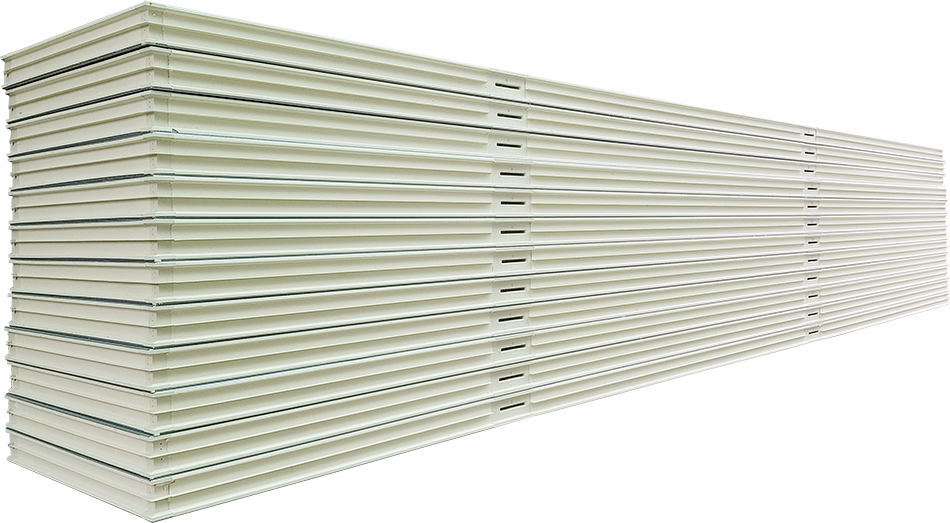

Urethane Panels for Refrigeration

- High-quality polyurethane panels with the best insulation properties

- By using PolyIsocyanurate Foam(PIR) which is one of the best insulating materials, our panels are able to maintain the strengths of PolyUrethane Foam(PUR) used in the past while improving fire retardancy, heat resistance and insulation.

냉장·냉동용 판넬의 장점

- 1기밀한 결합과 뛰어난 단열성

- 브림방식 혹은 화스너방식으로 판넬을 강력하게 결속시켜 냉기가 세어나갈 틈을 최소화 합니다.

- 2신속 · 편리한 시공

- 간편한 결합구조로 쉽고 빠르게 판넬을 조립할 수 있어 공사기간을 대폭 단축시킬 수 있습니다.

- 3고객맞춤 주문생산

- 고객의 요구대로 판넬의 폭과 길이를 자유자재로 생산할 수 있어 현장에서 자르거나 가공할 필요가 없습니다. (최대폭 900mm, 최대길이 10m)

- 44면 PVC샤시 마감

- 꼼꼼한 샤시마감으로 판넬의 오염과 변형을 예방하여 재사용이 가능하고, 외부충격에 보다 강합니다.

- 5간편한 이설 · 증설

- 판넬 훼손없이 간편하게 해체가 가능하여 손쉽게 이설·증설할 수 있습니다.

Reason for Selecting Leehwa Polytech’s Urethane Panels

- 1Excellent Insulation

- We have been able to maintain the air tightness and durability of our panels through the automation of our entire production process and upgrading to the latest equipment. Therefore, you can expect our panels to have excellent insulation properties. (high pressure foam injector, hot press, etc.)

[high-pressure foam injection machine]

[high-pressure foam injection machine]

[10m hot press]

[10m hot press]

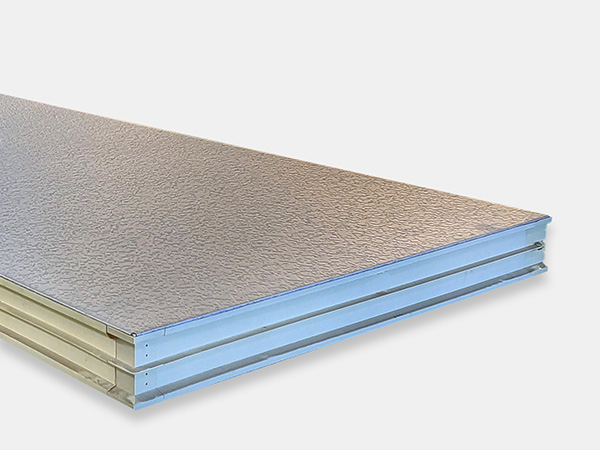

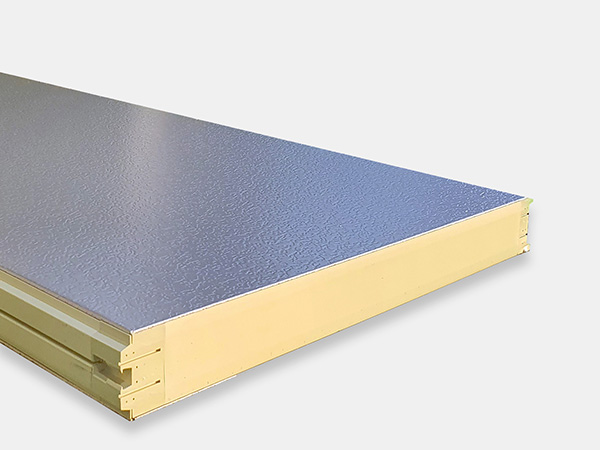

- 2Diverse Designs

- We produce urethane panels in 4 colors in order to provide consumers with a wider range of options which is a step forward when compared to the simple panels of the past.

『Gold flower (new product)/Silver stucco/Ivory/Stainless steel』

[골드스타코]

[골드스타코]

[실버스타코]

[실버스타코]

[아이보리스타코]

[아이보리스타코]

[아이보리]

[아이보리]

[화이트]

[화이트]

[스테인리스]

[스테인리스]

- 3New Assembly Method and Fittings

- Panel assembly is easier and joints are stronger due to the use of our unique assembly method and a new saw tooth connector (bracket).

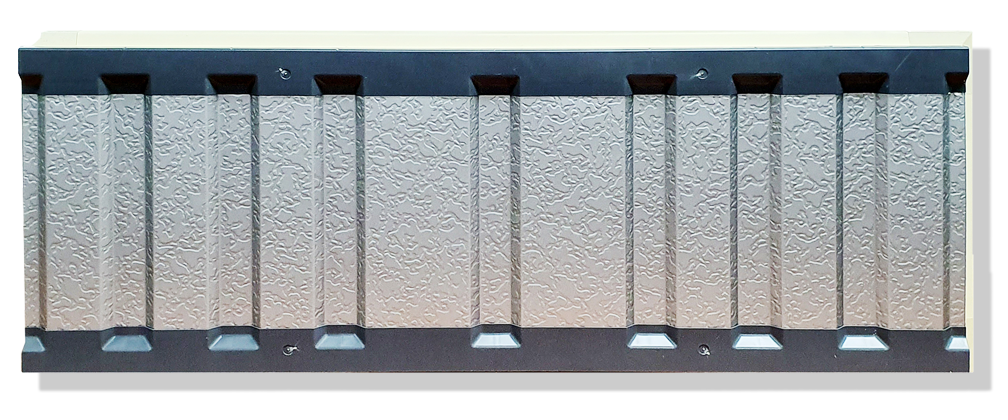

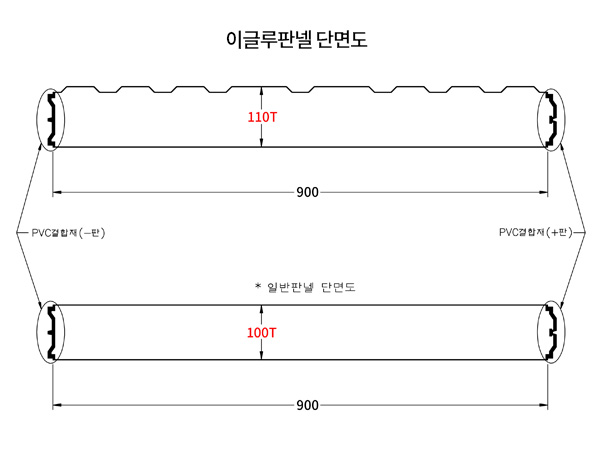

★New★ Leegloo Corrugated Panels

Features of Leegloo Corrugated Panels!

- 냉동·냉장 능력 극대화

기존 판넬에 일정한 굴곡을 적용함으로써, 저온창고 내부의 냉기순환성을 향상시켜 냉동·냉장 능력을 극대화 하였습니다!

- 단열성·강도 업그레이드

최대 110T 두께의 판넬로서, 더욱 향상된 단열성과 강도를 기대할 수 있습니다!

- 시공의 용이성

판넬 자체에 깔끔한 사출물로 마감되어 있기 때문에 판넬 시공 시 천장·바닥 내부앵글 작업을 생략해도 되므로 작업시간이 단축됩니다!

타사 골판넬에 비해 코너부분의 공간을 확보하여 실리콘 작업 등 시공이 더욱 용이합니다!

- 칸막이벽체 전용 내부앵글 별도 제공!

- 업계유일 신형 골판넬

기존 골판넬의 단점을 개선한 업계 유일의 신형 골판넬입니다! (특허출원)

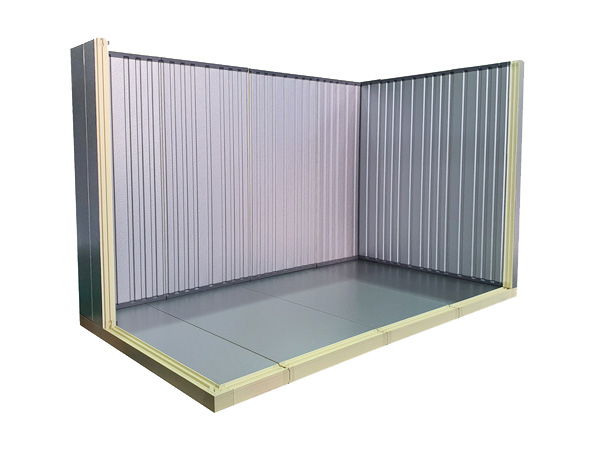

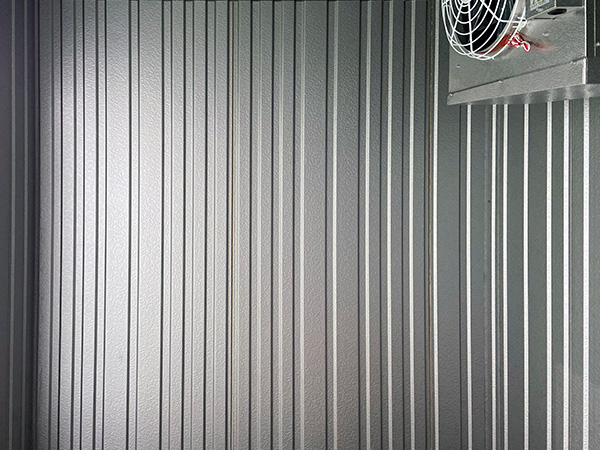

Image of Installed Leegloo

Brim-type Panel

100T·125T·150T 생산 가능

5가지 컬러·디자인 선택 가능

최대 10미터까지 생산 가능

Characteristics of Brim-type Panels

- Unique corner connection of Leehwa Polytech’s panels

- Tight joints with superb insulation

- Bracket (mold injected brim connectors) : steel brackets used to fix large size panels to the ceiling to support its weight during the construction of cold storage rooms over 66㎡

- Selection of 4 colors·designs

- Contains flame retardant materials: resistant to fire because it contains flame retardant materials (TCPP) with a flame retardancy rating of 2 to 3

- Clean molding finish through the use of the finest plastic finishes

Fastener-type Panel

[Fastener (minus)]

[Fastener (minus)]

[Fastener (plus)]

[Fastener (plus)]

부식이 없는 PVC화스너 채택

100T·125T·150T 생산 가능

5가지 컬러·디자인 선택 가능

최대 10미터까지 생산 가능

Characteristics of Fastener-type Panels

- Separate Orders

Each panel for walls·ceiling·floor can be produced as fastener or brim-types according to customer requirements.

- Compatibility with Brim-type Panels

Fasteners are inserted into PVC casing so that they are compatible with existing brim-type panels

- Use of PVC Fasteners

PVC fasteners used to prevent corrosion on the panel connections

- Ideal for Mid/Large-sized Cold Storage Warehouses

It is ideal for easy construction of mid/large-sized cold storage warehouses.

- Incorporated Door

In order to make installation easy, integrated doors are used instead of detachable ones.

New Divider Panel Launched!

[ Disadvantage

[ Disadvantage: insulation degradation occurs due to cold air penetrating the into the empty spaces of the chassis frame ] Old divider panel (grooved edges)

[ Advantage

[ Advantage : chassis frame finished with a flat surface to maximize insulation and air tightness! ] ★ New divider panel (flat edges) ★

Panel Assembly Steps

1. Base Frame (zinc angles) Installation

1. Base Frame (zinc angles) Installation

Decide where to install the panels. Place the base frame on the location and make sure the frame is level.

2. Floor Panel Placement

2. Floor Panel Placement

Place the floor panels on the base frame with consideration for drainage. Secure the floor panel with U-shaped brackets and make sure boards are aligned properly.

3. Wall Panel Placement

3. Wall Panel Placement

Set the corner panel upright followed by the other panels one after the other. Make sure the panels do not fall over. If panels are installed on the wall of the building, apply a layer of silicone between the panel and wall to ensure adhesion.

4. Door Frame Assembly

4. Door Frame Assembly

Install the door frame.

5. Ceiling Panel Placement

5. Ceiling Panel Placement

Set the ceiling panels on top. Use a liner to adjust the spaces of the joints. Fill the space with silicone to ensure a tight seal.

6. Unit Cooler Installation

6. Unit Cooler Installation

Install the door and adjust hinges making sure to inspect all the parts fit properly. Next, install the unit cooler. Proceed to install the electrical wiring and perform a test run before completing the assembly.

Optimal Storage Temperature and Usage According to Panel Thickness

| Thickness | Optimal Temp. Range | Usage |

|---|---|---|

| 50~75㎜ | above 0°C | cool storage, cold storage |

| 100㎜ | -5 ~ 0℃ | cool storage, frozen storage |

| 125㎜ | -30 ~ -5℃ | frozen storage, freezing |

| 150㎜ | -40 ~ -30℃ | freezing, rapid freezing, ultra-low temp. storage |

Materials and Specification

| Category | Specification and Properties of Urethane Panel | |

|---|---|---|

| Material of Surface | Steel Sheet | 0.45㎜~0.5㎜ colored steel sheet |

| Zinc Plating | 60~90g/㎡ | |

| Surface Treatment | High heat-resistant coating | |

| Middle Insulation Layer | Material | PolyUrethane Foam(PUR) PolyIsocyanurate Foam(PIR) |

| Density | PUR:40±2㎏/㎥ PIR:50±2㎏/㎥ |

|

| Fire-resistance | self-extinguishing(fire retardant) | |

| Heat Transfer | less than 0.023kcal/m·hr·℃ | |

| Absorption Volume | less than 0.3g/100㎠ | |

| Applicable Temp. | -30~90℃) | |

| Adhesion Method | Self-adhesive | Self-adhesive |

| 결합 방식 | 결합 방식 | 브림타입(꺾쇠타입/날개타입) 화스너타입 |

Strength | Compressive Strength | more than 20N/100㎠ |

| Flexive Strength | more than 25N | |

| Dimensions | Thickness | 75T,100T,125T,150T |

| Effective Width | maximum 900㎜ | |

| Length | maximum 12M | |